Why Contract Manufacturing Services Matter

- 4lenspartnerships

- Oct 13

- 4 min read

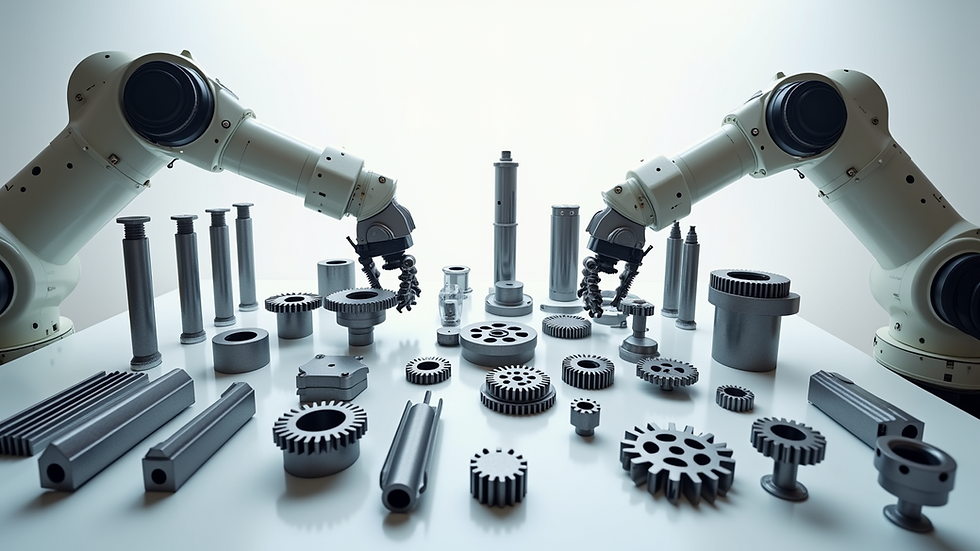

In today’s fast-paced industrial world, businesses face increasing pressure to deliver quality products quickly and efficiently. Managing every aspect of manufacturing in-house can be costly and complex. That’s where contract manufacturing services come in! These services offer a strategic way to streamline production, reduce costs, and focus on core business strengths. I want to share some valuable insights about contract services and why they matter so much for manufacturing and industrial clients.

Understanding Contract Services Insights

Contract manufacturing is a business model where a company outsources production to a third-party manufacturer. This approach allows companies to leverage specialized expertise, advanced technology, and flexible capacity without investing heavily in their own facilities. Contract services insights reveal that this model can transform how businesses operate by:

Reducing capital expenditure: No need to build or maintain expensive manufacturing plants.

Improving scalability: Easily adjust production volumes based on demand.

Accessing specialized skills: Benefit from manufacturers with deep industry knowledge.

Speeding up time to market: Faster production cycles and quicker product launches.

For example, a company producing electronic components might partner with a contract manufacturer that specializes in precision assembly and testing. This partnership ensures high-quality output while freeing the company to focus on design and marketing.

Contract services insights also highlight the importance of choosing the right partner. A reliable contract manufacturer acts as an extension of your business, sharing your commitment to quality and deadlines. This collaboration can lead to long-term success and innovation.

The Benefits of Contract Manufacturing Services

When you explore contract manufacturing services, you’ll find a range of benefits that can help your business thrive. Here are some key advantages:

Cost Efficiency

Outsourcing production reduces the need for large capital investments in equipment and facilities. You pay for what you need, when you need it. This flexibility helps manage cash flow and lowers operational risks.

Focus on Core Competencies

By delegating manufacturing tasks, your team can concentrate on product development, sales, and customer service. This focus often leads to better innovation and stronger market positioning.

Quality Assurance

Top contract manufacturers implement rigorous quality control processes. They have certifications and standards in place to ensure products meet or exceed expectations. This reliability builds trust with your customers.

Supply Chain Optimization

Contract manufacturers often have established supply chains and logistics networks. Partnering with them can simplify procurement, reduce lead times, and improve inventory management.

Access to Advanced Technology

Many contract manufacturers invest in cutting-edge machinery and automation. This access allows your products to benefit from the latest manufacturing techniques without additional investment.

Flexibility and Scalability

Whether you need a small batch or mass production, contract manufacturers can adjust quickly. This agility is crucial in industries with fluctuating demand or seasonal trends.

To make the most of these benefits, it’s essential to communicate clearly with your contract manufacturer. Define expectations, timelines, and quality standards upfront. Regular updates and site visits can help maintain alignment and address issues promptly.

How Risky Is Contract Manufacturing?

While contract manufacturing offers many advantages, it’s important to understand the risks involved. Managing these risks effectively can make the difference between a successful partnership and costly setbacks.

Quality Control Risks

Outsourcing production means relying on another company’s processes. If quality standards slip, your brand reputation can suffer. To mitigate this, choose manufacturers with strong quality certifications like ISO 9001 and conduct regular audits.

Intellectual Property Concerns

Sharing product designs and proprietary information with a third party carries risks. Protect your intellectual property through legal agreements such as non-disclosure agreements (NDAs) and carefully vet your partners.

Supply Chain Disruptions

Contract manufacturers depend on their own suppliers. Any disruption in their supply chain can delay your production. Diversify your supply sources and maintain open communication to anticipate and manage delays.

Communication Challenges

Distance and cultural differences can lead to misunderstandings. Establish clear communication channels, use project management tools, and schedule regular meetings to keep everyone on the same page.

Dependency Risks

Relying heavily on one contract manufacturer can create vulnerabilities. Consider having backup suppliers or multiple partners to reduce dependency risks.

By understanding these risks and implementing proactive strategies, you can enjoy the benefits of contract manufacturing while minimizing potential downsides.

Practical Tips for Choosing the Right Contract Manufacturer

Selecting the right contract manufacturing partner is critical. Here are some actionable recommendations to guide your decision:

Evaluate Experience and Expertise

Look for manufacturers with a proven track record in your industry. Ask for case studies or references.

Assess Quality Systems

Verify certifications and quality control processes. Request samples or pilot runs to test product quality.

Check Capacity and Flexibility

Ensure the manufacturer can handle your production volumes and scale as needed.

Review Financial Stability

A financially stable partner is less likely to face disruptions that affect your supply.

Visit Facilities

Whenever possible, tour the manufacturing site to observe operations and meet the team.

Clarify Communication and Support

Confirm how you will communicate and who your main contacts will be.

Negotiate Clear Contracts

Define terms related to pricing, delivery schedules, quality standards, and intellectual property protection.

Consider Location and Logistics

Proximity can reduce shipping costs and lead times. Also, consider the manufacturer’s ability to handle customs and regulatory compliance.

By following these steps, you can build a strong foundation for a successful partnership that supports your business goals.

Embracing Contract Manufacturing for Future Growth

Contract manufacturing services are more than just a cost-saving measure. They represent a strategic opportunity to innovate, grow, and compete in a challenging market. By partnering with the right contract manufacturer, you gain access to expertise, technology, and flexibility that can accelerate your success.

Remember, the goal is to create a seamless extension of your business. This means fostering trust, maintaining open communication, and aligning on shared objectives. When done right, contract manufacturing can help you meet customer demands faster, improve product quality, and optimize your supply chain.

If you’re ready to explore how contract manufacturing can transform your operations, start by researching reputable providers and reaching out for consultations. Your next big manufacturing breakthrough could be just a partnership away!

Let’s embrace the power of contract manufacturing services together and build a future where your manufacturing needs are met with precision, efficiency, and reliability!

Comments