Boost Your Industrial Manufacturing Efficiency

- 4lenspartnerships

- Oct 6

- 3 min read

In today’s competitive market, improving efficiency in industrial manufacturing is not just an option - it’s a necessity! Streamlining operations, reducing waste, and enhancing productivity can make a significant difference in your bottom line. I want to share practical insights and actionable strategies to help you optimize your industrial processes and achieve outstanding results.

Understanding Industrial Processes Optimization

Industrial processes optimization involves analyzing and improving the various steps involved in manufacturing to maximize efficiency and minimize costs. This can include everything from raw material handling to final product assembly. The goal is to create a seamless workflow that reduces downtime, improves quality, and accelerates production cycles.

To start, consider these key areas for optimization:

Process Mapping: Document every step in your production line to identify bottlenecks and redundancies.

Automation: Implement automated systems where possible to reduce manual errors and speed up repetitive tasks.

Data Analytics: Use real-time data to monitor performance and make informed decisions quickly.

Lean Manufacturing: Adopt lean principles to eliminate waste and focus on value-added activities.

By focusing on these areas, you can create a more agile and responsive manufacturing environment that meets customer demands efficiently.

Key Strategies to Boost Efficiency in Industrial Manufacturing

Efficiency gains come from a combination of technology, process improvements, and workforce engagement. Here are some proven strategies to boost your manufacturing efficiency:

Invest in Advanced Technology

Modern machinery and software can dramatically improve precision and speed. For example, CNC machines and IoT-enabled sensors provide real-time feedback and reduce errors.

Enhance Workforce Training

Skilled operators are essential for maintaining quality and efficiency. Regular training programs ensure your team stays updated on best practices and new technologies.

Optimize Supply Chain Management

Streamlining your supply chain reduces delays and inventory costs. Collaborate closely with suppliers and use just-in-time inventory systems to keep materials flowing smoothly.

Implement Preventive Maintenance

Scheduled maintenance prevents unexpected breakdowns that can halt production. Use predictive analytics to anticipate equipment failures before they happen.

Standardize Workflows

Consistent procedures reduce variability and improve quality. Document standard operating procedures (SOPs) and ensure everyone follows them.

By applying these strategies, you can create a more reliable and productive manufacturing process that supports your business goals.

What is the difference between manufacturing and industrial production?

Understanding the distinction between manufacturing and industrial production helps clarify where optimization efforts should focus.

Manufacturing refers specifically to the process of converting raw materials into finished goods. It involves various operations such as machining, assembling, and finishing.

Industrial Production is a broader term that includes manufacturing but also covers other activities like mining, energy production, and construction.

In essence, manufacturing is a subset of industrial production. When we talk about optimizing industrial processes, we often focus on manufacturing because it directly impacts product quality and delivery times.

Knowing this difference helps prioritize improvements in the areas that will yield the greatest efficiency gains.

Leveraging Technology for Industrial Processes Optimization

Technology plays a crucial role in modern industrial processes optimization. Here are some technologies that can transform your manufacturing operations:

Industrial Internet of Things (IIoT): Connects machines and devices to collect data and enable smarter decision-making.

Artificial Intelligence (AI) and Machine Learning: Analyze data patterns to predict maintenance needs and optimize production schedules.

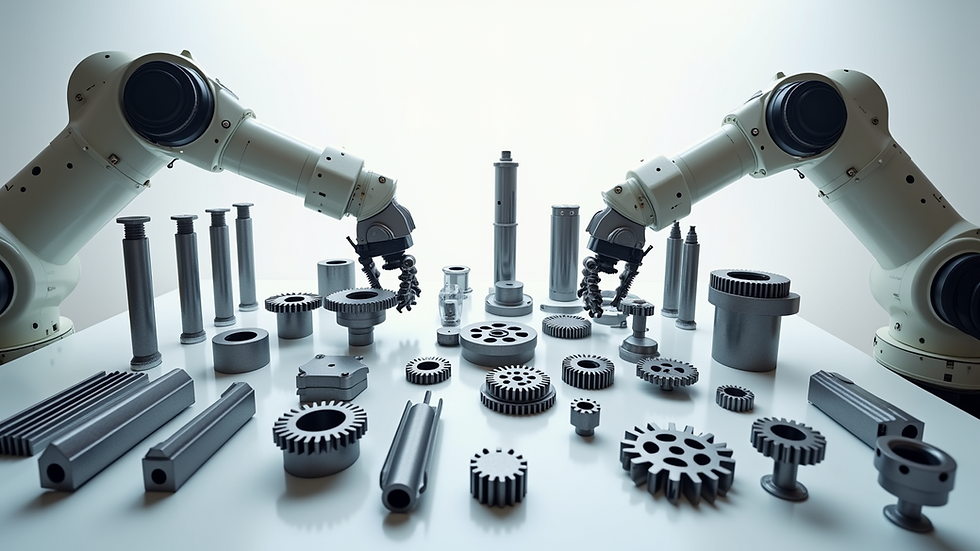

Robotics and Automation: Increase speed and precision while reducing labor costs.

Digital Twins: Create virtual models of your production line to simulate changes and identify improvements without disrupting operations.

Adopting these technologies requires investment but offers significant returns through increased efficiency and reduced downtime.

Taking Action: Steps to Start Your Efficiency Journey Today

Ready to boost your industrial manufacturing efficiency? Here’s a simple action plan to get started:

Assess Your Current Processes

Conduct a thorough review of your production line to identify inefficiencies and areas for improvement.

Set Clear Goals

Define what efficiency means for your operation - whether it’s reducing cycle time, lowering costs, or improving quality.

Engage Your Team

Involve employees at all levels to gather insights and foster a culture of continuous improvement.

Choose the Right Tools

Select technologies and methodologies that align with your goals and budget.

Implement Incrementally

Start with pilot projects to test changes before scaling up.

Monitor and Adjust

Use data to track progress and make adjustments as needed.

By following these steps, you can create a sustainable path to enhanced efficiency and stronger business partnerships.

For those looking to streamline their supply chain and meet custom manufacturing needs, partnering with experts in industrial manufacturing can provide a single-source solution that simplifies your operations and drives growth.

Optimizing your industrial processes is a journey that requires commitment and smart strategies. With the right approach, you can unlock new levels of productivity and build lasting success in the manufacturing sector. Let’s take these steps together and transform your operations for the better!

Comments