Mastering Industrial Manufacturing for Business Growth

- 4lenspartnerships

- Sep 8

- 3 min read

In today’s competitive market, mastering industrial manufacturing strategies is essential for any business aiming to grow and thrive. The manufacturing sector is evolving rapidly, driven by technological advances, changing customer demands, and global supply chain challenges. To stay ahead, companies must adopt smart, efficient, and scalable approaches that streamline operations and foster strong partnerships. Let’s explore how you can leverage these strategies to boost your business success!

Understanding Industrial Manufacturing Strategies

Industrial manufacturing strategies involve a set of planned actions and methodologies designed to optimize production processes, reduce costs, and improve product quality. These strategies focus on integrating technology, workforce skills, and supply chain management to create a seamless manufacturing ecosystem.

Some key components of effective industrial manufacturing strategies include:

Lean Manufacturing: Eliminating waste and improving efficiency by streamlining workflows.

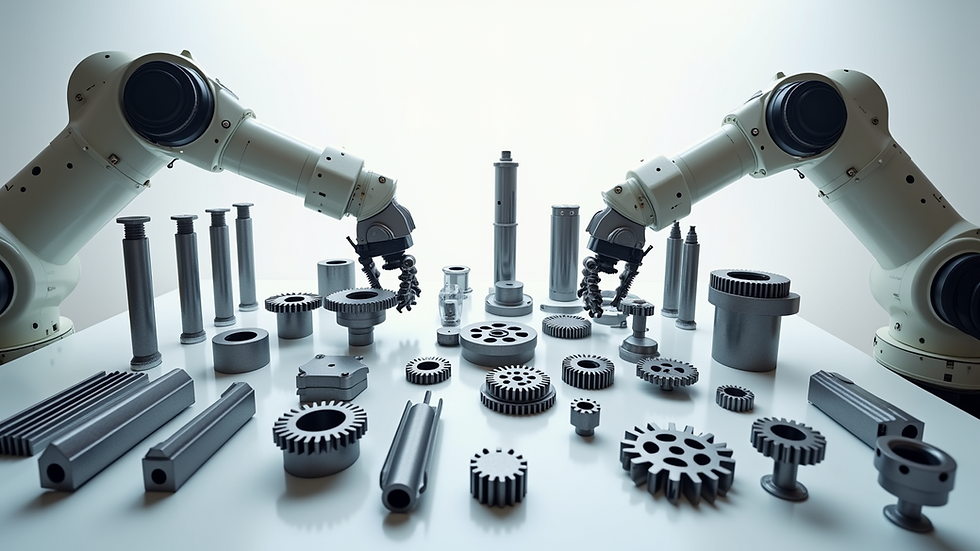

Automation and Robotics: Using machines to perform repetitive tasks, increasing speed and accuracy.

Quality Control Systems: Implementing rigorous checks to ensure products meet standards.

Supply Chain Integration: Coordinating with suppliers and distributors to reduce delays and costs.

Sustainability Practices: Reducing environmental impact through energy-efficient processes and materials.

By combining these elements, businesses can reduce lead times, lower operational costs, and deliver superior products to their customers.

Implementing Industrial Manufacturing Strategies for Growth

To implement these strategies effectively, start by assessing your current manufacturing processes. Identify bottlenecks, inefficiencies, and areas where technology can add value. Here’s a step-by-step approach:

Conduct a Process Audit: Map out every step in your production line. Look for delays, redundancies, and quality issues.

Invest in Technology: Consider automation tools, data analytics, and IoT devices to monitor and optimize operations.

Train Your Workforce: Equip your team with the skills needed to operate new technologies and follow best practices.

Enhance Supplier Relationships: Work closely with suppliers to ensure timely delivery of raw materials and components.

Focus on Continuous Improvement: Use feedback loops and performance metrics to refine processes regularly.

For example, a manufacturer might introduce robotic arms to handle assembly tasks, freeing up workers for more complex roles. Simultaneously, integrating real-time data analytics can help predict equipment failures before they happen, reducing downtime.

What is the difference between manufacturing and industrial manufacturing?

Understanding the distinction between manufacturing and industrial manufacturing is crucial for applying the right strategies.

Manufacturing generally refers to the process of producing goods from raw materials on a smaller or medium scale. It can include everything from handcrafted items to mass-produced consumer products.

Industrial manufacturing, on the other hand, focuses on large-scale production, often involving heavy machinery, complex supply chains, and high-volume output. It typically serves sectors like automotive, aerospace, electronics, and heavy equipment.

Industrial manufacturing demands more rigorous process control, advanced technology integration, and strategic supply chain management. This scale and complexity require specialized strategies to maintain efficiency and quality.

Leveraging Supply Chain Solutions for Seamless Operations

A critical part of mastering industrial manufacturing is managing the supply chain effectively. Supply chain disruptions can halt production and increase costs, so having a reliable, flexible supply chain is vital.

Here are some actionable recommendations:

Centralize Procurement: Use a single source solution for custom manufacturing needs to simplify ordering and reduce errors.

Build Strong Partnerships: Collaborate with suppliers who understand your business goals and can adapt to your demands.

Implement Just-in-Time Inventory: Reduce inventory costs by receiving materials only when needed.

Use Technology for Visibility: Employ supply chain management software to track shipments, inventory levels, and supplier performance in real time.

By streamlining your supply chain, you can reduce lead times, avoid stockouts, and respond quickly to market changes. This approach supports your overall goal of fostering lasting business partnerships and delivering consistent quality.

Driving Business Growth Through Innovation and Collaboration

Innovation is the engine that drives growth in industrial manufacturing. Embracing new technologies and collaborative approaches can open doors to new markets and improve profitability.

Consider these strategies:

Adopt Industry 4.0 Technologies: Integrate smart sensors, AI, and machine learning to optimize production and predict maintenance needs.

Collaborate with Partners: Work with technology providers, research institutions, and other manufacturers to share knowledge and resources.

Customize Solutions: Offer tailored products and services that meet specific client needs, differentiating your business.

Focus on Sustainability: Implement eco-friendly practices to meet regulatory requirements and appeal to environmentally conscious customers.

By continuously innovating and building strong partnerships, your business can stay competitive and expand its reach.

Mastering industrial manufacturing is not just about improving production; it’s about creating a resilient, efficient, and innovative business model. By adopting the right strategies, investing in technology, and fostering strong supply chain relationships, you can unlock new growth opportunities and build a sustainable future for your company. Ready to take your manufacturing operations to the next level? Let’s get started today!

Comments