What’s Next for Automation in Manufacturing?

- 4lenspartnerships

- Jun 23

- 4 min read

Updated: Jul 28

The manufacturing industry is undergoing a significant transformation through industrial automation. With the integration of advanced technologies, businesses are vastly improving efficiency, productivity, and safety standards. As we look toward the future, it's essential to understand what advancements are on the horizon and how they will affect the manufacturing landscape.

The Role of Industrial Automation in Modern Manufacturing

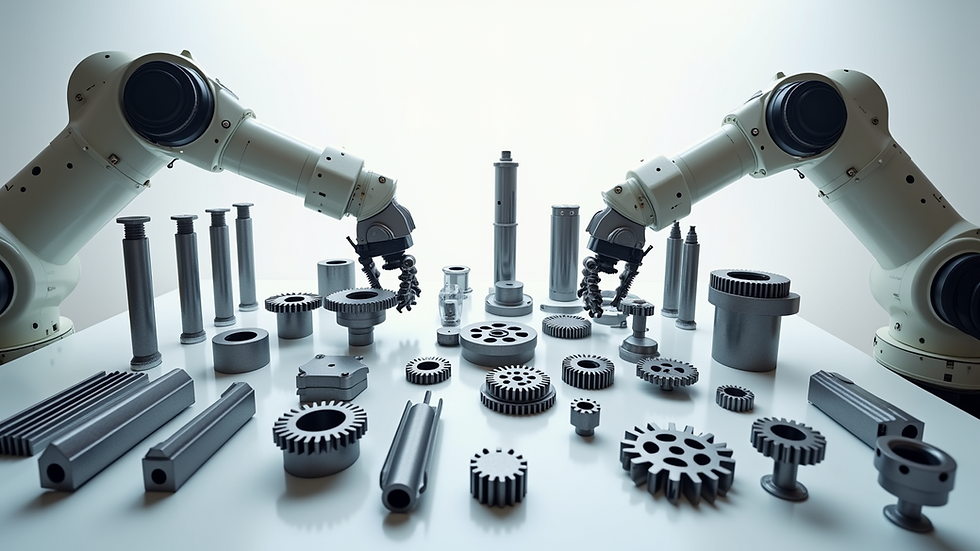

Industrial automation refers to the use of technology to automate manufacturing processes, reducing the need for human intervention. It encompasses robotics, control systems, and information technologies. This transformation not only enhances productivity but also improves the quality of products and services.

In manufacturing plants, automation can take many shapes. From robotic arms assembling cars to conveyor belts transporting goods, automation solutions are tailored to meet specific operational needs. According to a report by Statista, the global market for industrial automation is projected to reach $300 billion by 2026, emphasizing the sector's rapid growth and adoption.

One of the significant advantages of implementing industrial automation is cost savings. Automation minimizes labor costs and reduces human error, leading to decreased waste and improved product quality. As companies adopt more sophisticated automation technologies, they can scale operations efficiently, responding quickly to market demands and changes.

Key Technologies Shaping Industrial Automation

Several emerging technologies are at the forefront of industrial automation. These innovations are not only shaping how businesses operate but also opening new avenues for growth and efficiency.

1. Artificial Intelligence (AI)

AI is revolutionizing industrial automation by enabling machines to learn from data and make decisions in real time. For example, predictive maintenance powered by AI can anticipate machine failures before they happen, mirroring the shift towards more data-driven operations.

2. The Internet of Things (IoT)

The IoT integrates smart devices and sensors, allowing manufacturers to monitor operations in real time. This connectivity enables more informed decision-making and optimizes manufacturing processes. According to a report by McKinsey, implementing IoT can lead to productivity increases of 20%-30%.

3. Additive Manufacturing

Known as 3D printing, additive manufacturing allows for rapid prototyping and customization. Companies can create complex designs without needing expensive molds, reducing lead times and manufacturing costs.

What is the forecast for industrial automation?

The forecast for industrial automation is promising, driven by various factors. Industry 4.0, characterized by smart factories and interconnected systems, is expected to permeate more sectors. As businesses embrace digital transformation, key trends are likely to impact the future landscape.

Increased Adoption of Collaborative Robots (Cobots): Unlike traditional robots that operate independently, cobots work alongside human workers. This collaboration enables a safer environment while enhancing efficiency. MarketsandMarkets predicts that the cobot market will grow from $573 million in 2020 to $7.72 billion by 2026.

Edge Computing Innovations: With more machines connected to the IoT, edge computing minimizes latency by processing data closer to its source. This change improves response times and reduces bandwidth consumption, making industrial operations more efficient.

Growth of Autonomous Machinery: Autonomous vehicles and drones are set to play a pivotal role in logistics and supply chain management. Companies like Amazon are already experimenting with drone deliveries, showcasing the potential for revolutionizing shipping and distribution.

Challenges Facing Industrial Automation

Despite the potential for positive advancements, several challenges hinder the widespread adoption of industrial automation. A significant concern is the cybersecurity risk associated with interconnected devices and networks. As systems become more digitally reliant, protecting sensitive data from cyber threats is paramount.

Another challenge is the skills gap in the workforce. As automation technology advances, the demand for skilled labor that can manage and operate these technologies grows. Upskilling and reskilling current employees will be imperative to avoid potential talent shortages.

The Future of Industrial Automation: What Businesses Should Do

To thrive in an environment characterized by rapid technological changes, businesses must take proactive steps toward embracing industrial automation. Here are some essential recommendations:

Invest in Training and Development: Companies should prioritize upskilling their workforce. Offering regular training sessions and resources will enable employees to effectively use new technologies and remain competitive in the job market.

Prioritize Cybersecurity Measures: Investing in robust cybersecurity protocols is essential. Regular assessments and updates to security measures can help mitigate potential risks associated with interconnected systems.

Explore Pilot Programs: Before fully committing to extensive automation technologies, businesses could benefit from pilot programs. Testing new solutions on a smaller scale allows companies to evaluate effectiveness and identify any necessary adjustments.

Foster a Culture of Innovation: Encouraging an agile and innovative mindset among employees can facilitate adaptability to new technologies. Companies should inspire teams to propose automation solutions that enhance process efficiency and productivity.

Collaborate with Technology Partners: Partnering with technology experts can provide valuable insights and resources. Industry collaborations can lead to better alignment of automation strategies with business goals.

What Lies Ahead for the Manufacturing Sector?

As we check the pulse of the manufacturing industry, it's clear that the journey towards full automation is just beginning. With the

promising unprecedented changes, businesses must stay informed about emerging technologies and industry trends.

Innovation in manufacturing will continue to evolve, and the most successful organizations will be those that adapt quickly and embrace new technologies. By understanding the challenges and leveraging the opportunities, the manufacturing industry can pave the way for a more efficient and sustainable future.

In embracing industrial automation, companies not only enhance their operations but also contribute to a future where innovation drives growth and sustainability.

Comments