How Engineers Shape Custom Manufacturing Projects

- 4lenspartnerships

- Jul 28

- 4 min read

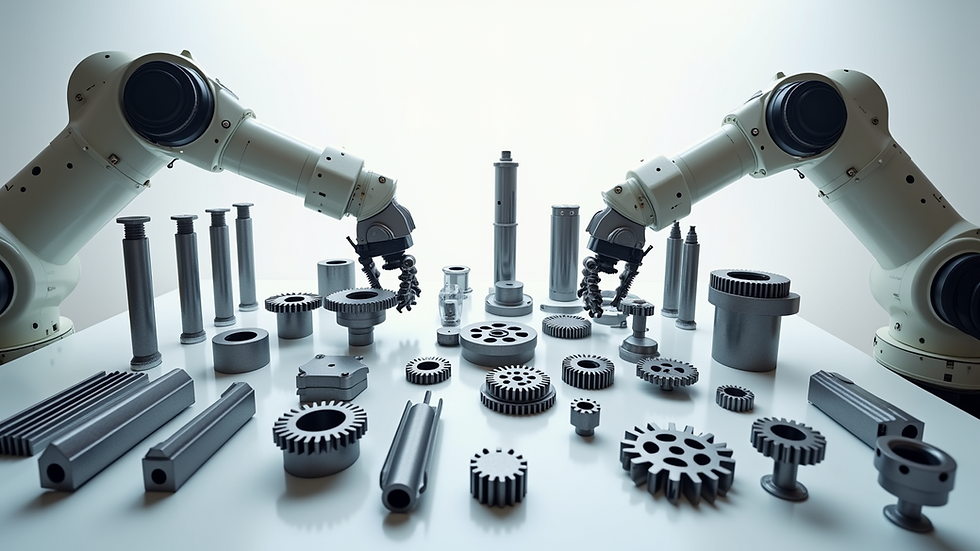

Custom manufacturing projects require a unique blend of creativity, precision, and technical knowledge. At the heart of these projects lies engineering expertise, which plays a crucial role in transforming ideas into tangible products. Engineers bring innovation, problem-solving skills, and technical know-how to every stage of the manufacturing process. This article explores how engineering expertise shapes custom manufacturing projects, ensuring quality, efficiency, and innovation.

The Role of Engineering Expertise in Custom Manufacturing

Engineering expertise is essential in custom manufacturing because it bridges the gap between concept and production. Engineers analyze project requirements, design solutions, and oversee the manufacturing process to ensure the final product meets specifications. Their involvement starts early, often during the ideation phase, and continues through prototyping, testing, and full-scale production.

One key aspect of engineering expertise is the ability to optimize designs for manufacturability. This means creating products that are not only functional but also cost-effective and easy to produce. Engineers use advanced software tools and simulations to predict how materials and components will behave, reducing the risk of errors and costly revisions.

For example, in the aerospace industry, engineers design custom parts that must withstand extreme conditions. Their expertise ensures these parts are lightweight yet durable, meeting strict safety standards. Similarly, in medical device manufacturing, engineers develop precise components that comply with regulatory requirements and perform reliably in critical applications.

How Engineering Expertise Drives Innovation and Efficiency

Engineering expertise fuels innovation by applying scientific principles and creative problem-solving to manufacturing challenges. Engineers explore new materials, technologies, and processes to improve product performance and reduce production time. This continuous innovation helps companies stay competitive and meet evolving customer demands.

Efficiency is another major benefit of engineering expertise. Engineers streamline workflows, automate repetitive tasks, and implement quality control measures to minimize waste and defects. They also collaborate closely with suppliers and production teams to ensure smooth operations.

For instance, engineers might introduce additive manufacturing (3D printing) to produce complex parts that traditional methods cannot achieve. This approach reduces lead times and material costs while enabling rapid prototyping. Additionally, engineers use data analytics to monitor production metrics and identify areas for improvement.

By integrating engineering expertise early in the project, manufacturers can avoid costly delays and rework. This proactive approach leads to faster time-to-market and higher customer satisfaction.

What does engineering and design do?

Engineering and design work hand-in-hand to bring custom manufacturing projects to life. Design focuses on the aesthetic and functional aspects of a product, while engineering ensures that the design is feasible and manufacturable. Together, they create detailed plans, specifications, and prototypes that guide production.

The design phase involves creating sketches, 3D models, and technical drawings that capture the product’s form and function. Designers consider user experience, ergonomics, and visual appeal. Once the design is finalized, engineers evaluate it for structural integrity, material selection, and manufacturing constraints.

During this phase, engineers perform simulations and stress tests to validate the design. They may suggest modifications to improve durability or reduce costs. This iterative process continues until the design meets all requirements.

After approval, engineers develop manufacturing instructions, select appropriate machinery, and coordinate with suppliers. They also oversee prototype fabrication and testing to ensure the product performs as intended.

This collaboration between design and engineering is critical for delivering high-quality custom products that satisfy both aesthetic and technical demands.

Practical Examples of Engineering Expertise in Custom Manufacturing

To better understand the impact of engineering expertise, consider these practical examples:

Automotive Industry: Engineers design custom engine components that improve fuel efficiency and reduce emissions. They use computer-aided engineering (CAE) tools to simulate airflow and thermal dynamics, optimizing performance.

Consumer Electronics: Engineering expertise enables the miniaturization of components, allowing manufacturers to produce sleek, compact devices without sacrificing functionality. Engineers also ensure heat dissipation and durability.

Industrial Equipment: Custom machinery often requires specialized parts designed to withstand heavy loads and harsh environments. Engineers select materials and design features that enhance reliability and ease of maintenance.

In each case, engineering expertise ensures that the final product meets customer expectations and industry standards. It also helps manufacturers innovate and adapt to changing market trends.

Leveraging Design and Engineering Services for Success

Partnering with professional design and engineering services can significantly enhance custom manufacturing projects. These services provide access to skilled engineers and designers who bring specialized knowledge and experience.

Benefits of leveraging such services include:

Access to advanced technology: Service providers often have state-of-the-art tools and software for design, simulation, and prototyping.

Cost savings: Outsourcing engineering tasks can reduce overhead and speed up project timelines.

Quality assurance: Experienced engineers implement rigorous testing and quality control processes.

Scalability: Services can scale resources up or down based on project needs.

By collaborating with expert teams, manufacturers can focus on core competencies while ensuring their custom projects are executed with precision and innovation.

The Future of Engineering Expertise in Custom Manufacturing

As technology evolves, engineering expertise will continue to shape the future of custom manufacturing. Emerging trends such as artificial intelligence, machine learning, and digital twins are transforming how engineers design and optimize products.

AI-powered design tools can generate multiple design alternatives quickly, helping engineers select the best options. Digital twins - virtual replicas of physical products - allow real-time monitoring and predictive maintenance, improving product lifecycle management.

Sustainability is also becoming a priority. Engineers are developing eco-friendly materials and energy-efficient manufacturing processes to reduce environmental impact.

In this dynamic landscape, engineering expertise remains indispensable. It empowers manufacturers to innovate, improve quality, and meet the demands of a rapidly changing market.

By understanding the critical role of engineering expertise in custom manufacturing, businesses can better appreciate the value of skilled engineers and designers. Their knowledge and creativity drive innovation, efficiency, and quality, turning ideas into successful products.

Comments